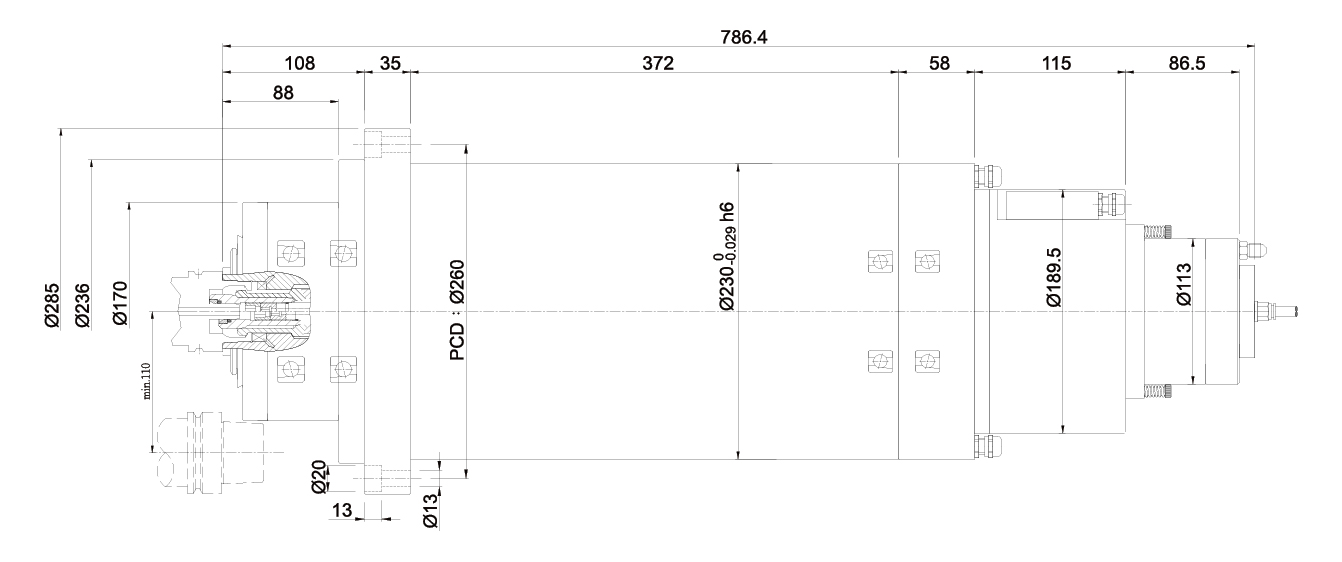

TH-230.08 (BiI112L/20000i) HSK-A63/BBT-40 20,000rpm

Product Information

| Type | TH-230.08 | ||

|---|---|---|---|

| FANUC BUILT-IN SPINDLE MOTOR |

BiI 112L/20000i | ||

| Spindle Ø | 230mm | ||

| Maximum Speed (Oil-Air) | 20,000rpm | ||

| Bore diameter of front bearings | 70mm | ||

| Rigidity | Axial (N/µm) |

Standardised or According to customer needs. It is available to increase the static rigidity, but the maximum speed will be reduced. |

|

| Radial (N/µm) |

|||

| Low winding | S1 kW | 15kW ab Drehzahl:2,000~4,000rpm |

|

| S1 Torque (Nm) | 80Nm ab Drehzahl:~2,000rpm |

||

| S2/S3 kW | 18.5kW(S3-25%) ab Drehzahl:1,500~4,000rpm |

||

| S2/S3 Torque (Nm) |

118Nm(S3-25%) ab Drehzahl:~1,500rpm |

||

| High winding | S1 kW | 18.5kW ab Drehzahl:8,000~20,000rpm |

|

| S1 Torque (Nm) | 22Nm ab Drehzahl:~8,000rpm |

||

| S2/S3 kW | 22kW(S2-15min) ab Drehzahl:5,000~20,000rpm |

||

| S2/S3 Torque (Nm) |

42Nm(S2-15min) ab Drehzahl:~5,000rpm |

||

| Tool Interface | HSK-A63 BBT-40 |

||

| Spindle Cooling | Cooling capacity:6,000Kcal/hr (at25℃) Water cooling /Oil cooling |

||

| Spindle Weight | 180kg | ||

| Integral Encoder For Closed-Loop Control |

Standard | ||

| Coolant Through Shaft (CTS) | Option | ||

| Tool Position Sensors | Proximity switches / Analog sensor |

||

| Front Bearing Temperature Sensor |

Standard | ||

Also available with Oil cooling. This cooling leads to motor power reduction.

Also available with grease lubrication. This lubrication leads to speed reduction.

Low winding kW

Low winding kW Low winding Nm

Low winding Nm High winding kW

High winding kW High winding Nm

High winding Nm

Compare Others Specifications

| Type | TH-190.01 | TH-230.01 | TH-230.04 | TH-230.08 | TH-230.13 | |

|---|---|---|---|---|---|---|

| FANUC BUILT-IN SPINDLE MOTOR |

BiI 112S/20000i | BiI 112L/15000i | BiI 112L/15000i | BiI 112L/20000i | BiI 112L/20000i | |

| Spindle Ø | 190mm | 230mm | 230mm | 230mm | 230mm | |

| Maximum Speed (Oil-Air) Also available with grease lubrication. This lubrication leads to speed reduction. |

20,000rpm | 15,000rpm | 10,000rpm | 20,000rpm | 12,000rpm | |

| Bore diameter of front bearings | 70mm | 70mm | 100mm | 70mm | 70mm | |

| Rigidity | Axial (N/µm) |

180N/µm | Standardised or According to customer needs. It is available to increase the static rigidity, but the maximum speed will be reduced. |

|||

| Radial (N/µm) |

200N/µm | |||||

| Low winding | S1 kW | 7kW | 15kW | 15kW | 15kW | 15kW |

| S1 Torque (Nm) | 31Nm | 95Nm | 95Nm | 80Nm | 80Nm | |

| S2/S3 kW | 11KW(S3-15%) | 18.5kW(S3-15%) | 18.5kW(S3-15%) | 18.5kW(S3-25%) | 18.5kW(S3-25%) | |

| S2/S3 Torque (Nm) |

60Nm(S3-15%) | 167Nm(S3-15%) | 167Nm(S3-15%) | 118Nm(S3-25%) | 118Nm(S3-25%) | |

| High winding | S1 kW | 11kW | 18.5kW | 18.5kW | 18.5kW | 18.5kW |

| S1 Torque (Nm) | 18Nm | 35Nm | 35Nm | 22Nm | 22Nm | |

| S2/S3 kW | 18.5kW(S2-10min) | 22kW(S2-15min) | 22kW(S2-15min) | 22kW(S2-15min) | 22kW(S2-15min) | |

| S2/S3 Torque (Nm) |

29Nm(S2-10min) | 42Nm(S2-15min) | 42Nm(S2-15min) | 42Nm(S2-15min) | 42Nm(S2-15min) | |

| Tool Interface | HSK-A63 BBT-40 |

HSK-A63 BBT-40 |

HSK-A100 BBT-50 |

HSK-A63 BBT-40 |

HSK-A63 BBT-40 |

|

| Spindle Cooling | Water cooling Also available with Oil cooling. This cooling leads to motor power reduction. |

|||||

| Spindle Weight | 87kg | 210kg | 230kg | 180kg | 230kg | |

| Integral Encoder For Closed-Loop Control |

Option | Standard | Standard | Standard | Standard | |

| Coolant Through Shaft (CTS) | Option | Option | Option | Option | Option | |

| Tool Position Sensors | Proximity switches / Analog sensor | |||||

| Front Bearing Temperature Sensor |

Standard | Standard | Standard | Standard | Standard | |

Related Products