TH-230.23 (18.5/22kW) HSK-A100/BBT-50 12,000rpm

Product Information

| Type | TH-230.23 (400V) |

||

|---|---|---|---|

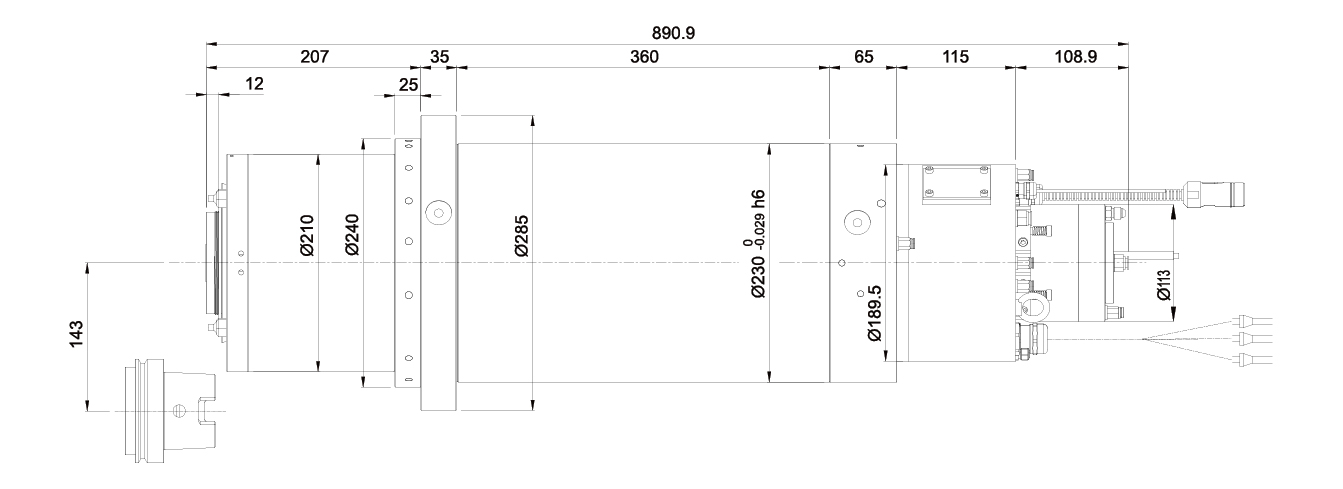

| Spindle Ø | 230mm | ||

| Maximum Speed (Oil-Air) | 12,000rpm | ||

| Bore diameter of front bearings | 100mm | ||

| Rigidity | Axial (N/µm) |

Standardised or According to customer needs. It is available to increase the static rigidity, but the maximum speed will be reduced. |

|

| Radial (N/µm) |

|||

| Frequency Max. (Hz) | 800Hz | ||

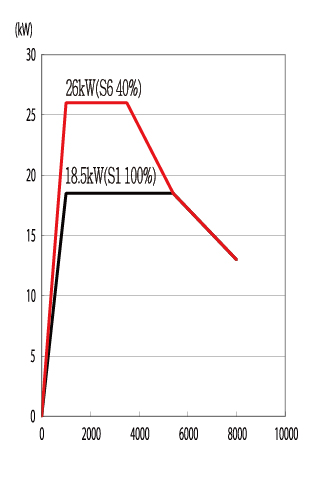

| Low winding | S1 kW | 18.5kW at speed:1,000~5,400rpm |

|

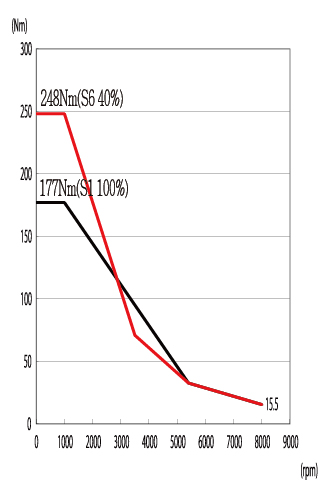

| S1 Torque (Nm) |

177Nm at speed:~1,000rpm |

||

| S1 Current (A) |

60A | ||

| S6-40% kW | 26kW at speed:1,000~3,500rpm |

||

| S6-40% Torque (Nm) |

248Nm at speed:~1,000rpm |

||

| S6-40% Current (A) |

84A | ||

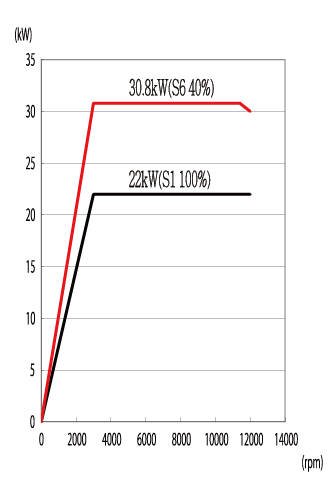

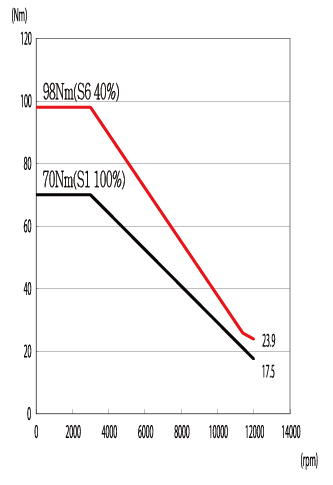

| High winding | S1 kW | 22kW at speed:3,000~12,000rpm |

|

| S1 Torque (Nm) |

70Nm at speed:~3,000rpm |

||

| S1 Current (A) |

56A | ||

| S6-40% kW | 30.8kW at speed:3,000~12,000rpm |

||

| S6-40% Torque (Nm) |

98Nm at speed:~3,000rpm |

||

| S6-40% Current (A) |

78A | ||

| kW (Peak Power) | 40kW | ||

| Tool Interface | HSK-A100 BBT-50 |

||

| Spindle Cooling unit | Cooling capacity:6,000Kcal/hr (at25℃) Water cooling /Oil cooling |

||

| Spindle Weight | 210kg | ||

| Integral Encoder For Closed-Loop Control |

Option | ||

| Coolant Through Shaft (CTS) | Option | ||

| Tool Position Sensors | Proximity switches / Analog sensor |

||

| Front Bearing Temperature Sensor |

Standard | ||

Also available with grease lubrication.

This lubrication leads to speed reduction.

Low Winding KW

Low Winding KW Low Winding Nm

Low Winding Nm High Winding KW

High Winding KW High Winding Nm

High Winding Nm

Compare Others Specifications

| Type | TH-230.23 (400V) |

TH-230.24 (400V) |

|||

|---|---|---|---|---|---|

| Spindle Ø | 230mm | 230mm | |||

| Maximum Speed (Oil-Air) Also available with grease lubrication. This lubrication leads to speed reduction. |

12,000rpm | 15,000rpm | |||

| Bore diameter of front bearings | 100mm | 70mm | |||

| Rigidity | Axial (N/µm) |

Standardised or According to customer needs. It is available to increase the static rigidity, but the maximum speed will be reduced. |

|||

| Radial (N/µm) |

|||||

| Frequency Max. (Hz) | 800Hz | 1,000Hz | |||

| Low winding | S1 kW | 18.5kW | 15kW | ||

| S1 Torque (Nm) |

177Nm | 136Nm | |||

| S6-40% kW | 26kW | 21.1kW | |||

| S6-40% Torque (Nm) |

248Nm | 196Nm | |||

| at speed | 1,000rpm | 1,050rpm | |||

| High winding | S1 kW | 22kW | 18.5kW | ||

| S1 Torque (Nm) |

70Nm | 55Nm | |||

| S6-40% kW | 30.8kW | 26kW | |||

| S6-40% Torque (Nm) |

98Nm | 77.6Nm | |||

| at speed | 3,000rpm | 3,200rpm | |||

| kW (Peak Power) | 40kW | 32kW | |||

| Tool Interface | HSK-A100 BBT-50 |

HSK-A80 | |||

| Spindle Cooling | Water cooling /Oil cooling | ||||

| Spindle Weight | 210kg | 170kg | |||

| Integral Encoder For Closed-Loop Control |

Option | Option | |||

| Coolant Through Shaft(CTS) | Option | Option | |||

| Tool Position Sensors | Proximity switches / Analog sensor | ||||

| Front Bearing Temperature Sensor |

Standard | Standard | |||

Related Products